Ranpak is expanding its automation solutions at Walmart’s distribution centers, the company announced Tuesday.

Under the multiyear agreement, Walmart will install Ranpak’s AutoFill machines at sites in the Chicago, Dallas, Philadelphia and Sacramento, California, metro areas. Walmart already uses this equipment at an Indianapolis-area fulfillment center, where it automates void filling and box closing to increase productivity.

This is the second major deal Ranpak has landed this year with an e-commerce giant. In January, Amazon agreed to spend $400 million on an eight-year deal to acquire up to 18.7 million Ranpak shares, which will amount to an estimated 17% of the company’s shares when completed.

“I don't think it's easy to sign commercial and strategic deals the way we have with the two largest, most important retailers and e-commerce players,” said CEO Omar Asali. “I certainly am very proud that that's where we are, and I'm very proud of our team. It's really nice to get the endorsement of the largest players out there.”

Asali, who has been the Ohio-based company’s CEO since 2019, said Ranpak still will invest in the business segment that manufactures packaging. Concurrently, a large part of the company’s strategy is to push toward more automation innovation and using artificial intelligence in its equipment offerings.

“I know it’s fashionable for everybody to talk about AI. But we are taking those investments very seriously, because we think that's going to be key to our journey in terms of winning market share and winning with big accounts,” Asali said.

Asali spoke with Packaging Dive about topics including AI-enabled automation, sustainability, navigating economic uncertainty, and predictions for the traditionally busy upcoming holiday season.

This interview has been edited for length and clarity.

PACKAGING DIVE: This Walmart deal is the second major one you've announced with an e-commerce giant this year. Is your strategy now to move more toward these large enterprise customers instead of serving smaller individual customers?

OMAR ASALI: No, I would say it's in addition to; It's not to move away from anything.

We're a 50-year-old company. The legacy business has been around packaging, all sustainable, all fiber-based. We have zero exposure to plastic, and we've partnered a lot with small and medium-sized enterprises and help them ship product.

We've done a few deals with some of the larger enterprises. I would say, the last couple of years we've put more emphasis on making sure we're winning our market share with the large enterprises, because that's where we were under indexed. But it's certainly in addition to covering the small and medium-sized enterprises — it's not in lieu of.

The Walmart deal is for your machinery related to void fill, as opposed to rightsized boxmaking equipment — and rightsizing has been a hot topic for the last few years. What kind of demand are you seeing for these two different technologies, and how do you balance your focal areas?

We're seeing very robust demand for automation. Whether it's rightsizing, whether it's the automatic void filling, whether it's bagging, even whether it's wrapping or mailer on demand, we're seeing very robust need for these products.

It's driven by a couple of things. One is just the amount of shipments that the large players are shipping. And to handle that type of volume, they need more automated solutions.

Two, just labor shortages and labor issues, frankly. More recently, even some of the immigration changes are adding pressure to these guys and their needs as we enter peak season later this year. Plus, probably some of the tax benefits around when you're investing in equipment and getting accelerated depreciation.

I think it’s a whole host of reasons. All these factors are increasing the level of conversation we're having with customers.

You mentioned seasonal pickup during the holiday season. But we're seeing a lot of economic pressure right now on consumers and reduced buying in certain sectors. Are you concerned about that?

I am concerned about it in terms of how concentrated the activity is. Meaning, I would love to see a lot more breadth in economic activity, where smaller enterprises, medium-sized enterprises, large enterprises are doing well and growing.

What I am seeing is the pressure that you've highlighted is applying more to smaller players. The large players are moving a lot of volume, and they continue to grow. So despite, let's call it maybe more uncertainty around the consumer, I think the larger players, given their speed, their efficiency, given how competitive they can be from a price and cost standpoint, they continue to win market share and continue to grow.

My personal expectations for peak season are pretty positive. From all the indications that we have today, we actually think peak season this year is going to be quite robust. It might be more concentrated in terms of the number of players that are winning market share, but overall, we think activity is going to be robust.

During your second-quarter earnings call this month, you repeatedly mentioned the challenging economic environment, plus a 3% reduction in headcount at Ranpak since April and a business reorganization in July. But at the same time, you projected growth in the second half of the year and that it will be an “inflection point.” Explain that in more detail.

Like any other company, we strive to be efficient. So sometimes that pruning and some of the headcount reduction are just necessary to continue to be efficient and continue to offer competitive pricing to customers. So we will continuously do that and cost improvements and bringing efficiencies to our business.

This is a bottom-up view based on us talking to a lot of customers — Ranpak has 36,000 users in 50 countries and we talk to a lot of these customers to understand their demands. We try to forecast with them, sort out their needs as we enter peak season. What we're hearing is in e-commerce, people are expecting a pretty good season in the United States. People on the industrial activity have a little bit more of a question mark about the outlook on the economy, and, in particular, in light of tariffs.

In Europe, in e-commerce, it looks a little bit more challenged. So that's not as robust. Industrial activity is starting to pick up now, but it was a bit weaker. So when you put all these factors together, and our geographic footprint and the businesses we have in Australia and Japan, that's what's giving us confidence in the second half of the year. We think a lot of activity is going to be driven by the large enterprise accounts, in particular in e-commerce.

Speaking of those large accounts, let’s go back to your Amazon deal in January. Why does that matter to your company?

It matters a lot. Because this is how we at Ranpak get better, by servicing these clients that are very demanding, these clients that move a lot of product. They push us to be more efficient. They push us on innovation, on R&D. They push us in our paper business and in our automation business. And that, just frankly, makes us a better company.

To me, deepening a partnership with someone like an Amazon and like a Walmart has tremendous tangible benefits to us as a business, as we continue to scale our company, continue to win market share and continue to be a leader in innovation and in technology.

The world is changing. Every industry is changing, including ours, thanks to AI, robotics, automation. These are not clichés or words that we use lightly. These are words where we're investing a lot of money to make our products and our solutions better.

The biggest validation is when the largest customers in the world come and say, "We want to sign a strategic partnership with you, because we like how you're innovating and how you're using technology.”

Talk more about the relationship between AI and your technologies and the impact that has on e-commerce packaging and operations.

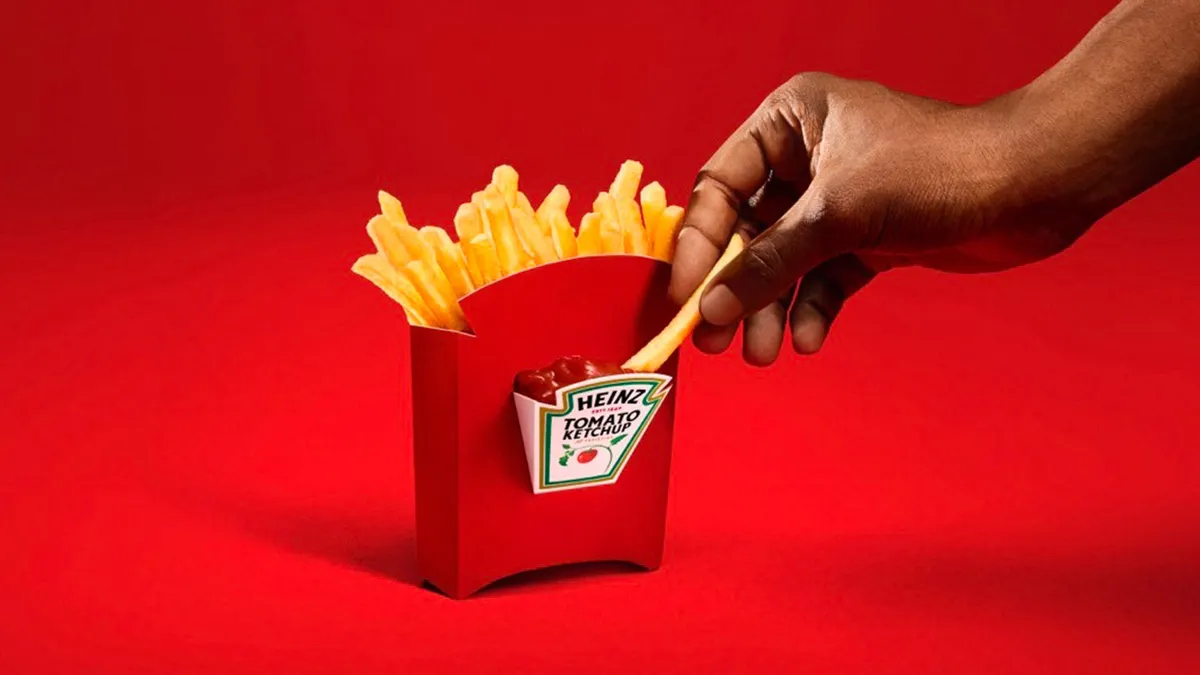

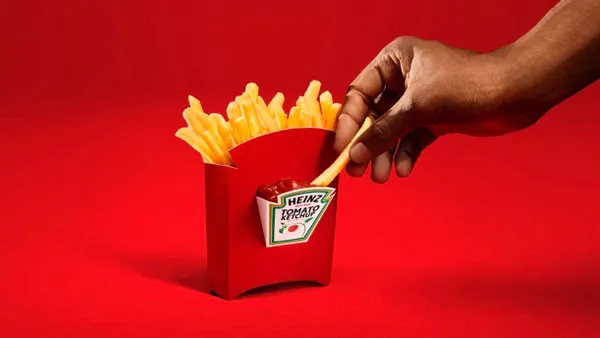

I'll use the AutoFill, which is the deal that we just signed with Walmart, as an example.

The AutoFill includes a computer vision system called DecisionTower. Think about boxes being erected, and these boxes are filled with items. They go through our vision system, which gets exact dimensions and exact volumetric data and exact data around the void — including flap angles, thickness of flaps in the box, including any items that are transparent, that are in the box, that are tough to detect. We built a very robust algorithm to get specific data that then is fed into our machines to dispense the right amount of paper, and then ultimately, that box is sealed with tape.

All of that is done without the human touch. It's all done in an automated fashion. Then our customer is getting a lot of data on the content, as well as getting data from our vision system around all the dimensions that they're shipping. It helps streamline from a cost standpoint, it helps reduce waste, it helps increase speed. We're providing them, through our vision system data and analytics, information that's making their end-of-line operation faster and better. Then it keeps making our equipment better as we build more and more data inside our algorithm, and we keep perfecting our solution.

The applicability of AI is across the board in our automation. It's literally in every product. We're trying to inject more and more AI, including not just in automation, but in manual pack stations to make manual packers better.

AI also has applicability to your rightsized box equipment, right?

100%. It’s helping our uptime. We have a vision system both before our equipment and after our equipment.

After our equipment for quality control, to assure our customers that everything was done properly.

Before our equipment, we're using that vision and its 2D and 3D technology in order to ensure the uptime of our equipment. If there's a problem with the box, instead of it going to our equipment and jamming it, it'll get diverted. And that way, the machine’s uptime is maintained. In the automation business, in order to deliver ROI, the most important metric is your uptime. And we use AI to help our uptime for our equipment, so we continue to deliver ROI.

Physical AI and computer vision is truly transformational in our company and in how we're approaching solutions. And in the last year, we've made tremendous progress, given basically the evolution of AI and the tools it has given us to make our solutions more robust.

Ranpak frequently references its sustainability goals. Right now we're seeing a lot of companies pivot from focusing on 2025 goals to 2030 targets. What are you focused on sustainability-wise going forward?

We are focused on increasing recycled content in our fiber — that's one of our goals in the upcoming years. We are focused on postconsumer waste and using that material as well. We are focused on moving to 100% FSC and SFI certified, so that we're using best forestry practices when it comes to us securing product from our vendors.

We're increasing our electric footprint. In Europe, we're pretty advanced in that, but in North America, it's early in our journey. We're starting with more hybrid vehicles, and then we're going to move to more electrification.

We're on our journey in scope 1, in scope 2, ultimately in scope 3, on reducing our greenhouse emissions. So these are sort of the key anchors that we as a company are focused on.

We continue to track toward our goals, and we will fulfill our obligations.