The choice between mailers and boxes has traditionally meant trading speed for protection. Mailers offer efficiency, while boxes provide the cushioning needed for fragile items. This binary approach creates inefficiencies across thousands of shipments, particularly as consumer expectations and regulatory requirements intensify.

The Hidden Cost of Traditional Shipping Formats

Boxes require assembly time, void-fill materials and warehouse space for inventory. Dimensional-weight pricing adds further pressure, with carriers charging based on package size rather than actual weight. Meanwhile, standard mailers often lack adequate protection. According to the 2025 Ryder E-Commerce Consumer Study, 25% of shoppers returned purchases because items arrived damaged. For fulfillment centers processing 10,000 orders weekly, even a 5% damage rate translates to 500 problem shipments per week. The impact extends beyond replacement costs to include return shipping expenses, labor costs for processing returns, inventory write-offs and lost customer acquisition costs.

Regulatory and Consumer Pressure for Sustainability

Consumer expectations and regulations are forcing brands to rethink their packaging. Shoppers increasingly favor environmentally responsible brands, making sustainable packaging a growth driver, not a tradeoff. At the same time, tightening laws like California’s SB 54 and expanding Extended Producer Responsibility requirements are accelerating the shift.

Engineering a Hybrid Solution

TemperPack's WaveKraft® mailers were designed to bridge the gap between traditional mailers and corrugated small boxes. Developed at the company's Proving Ground facility, the recyclable, padded mailers use a paper-based material providing ¼ inch of built-in protective cushioning.

Testing at the Proving Ground showed WaveKraft mailers deliver between 50% and 80% greater shock absorption compared to plastic mailers, macerated paper mailers and other recyclable cushioned alternatives. Drop tests demonstrated the mailers could protect fragile items including eyeshadows, nail polish and books, as well as materials such as acrylics and plastics. The construction provides radial support, cushioning and structural integrity through an advanced paper-based design.

Operational Efficiency Gains

WaveKraft mailers eliminate box assembly entirely, requiring no folding, taping or void fill. Available in three sizes, the mailers accommodate wider and bulkier products that previously required boxing. Based on estimated time savings of 45 to 90 seconds per package, a facility shipping 10,000 boxes per week could save approximately 15,000 minutes, or over 250 labor hours weekly. Reduced material usage also means lower storage space requirements, allowing fulfillment centers to consolidate from multiple box sizes and void fill options to a streamlined mailer inventory.

Real-World Recyclability

Most padded mailers are very difficult to recycle, based on their construction methods or material composition. Most plastic bubble and poly mailers are made from #4 plastics, which are not accepted in curbside recycling programs, require separate collection streams, and have a very limited market as a feedstock for new materials.

WaveKraft mailers are engineered to sort easily with cardboard and paper at materials recovery facilities and are considered “Widely Recyclable” by How2Recycle®. This matters as sustainability expectations continue to rise, with increased scrutiny around recyclability claims and lifecycle impacts.

A Wide Range of Applications

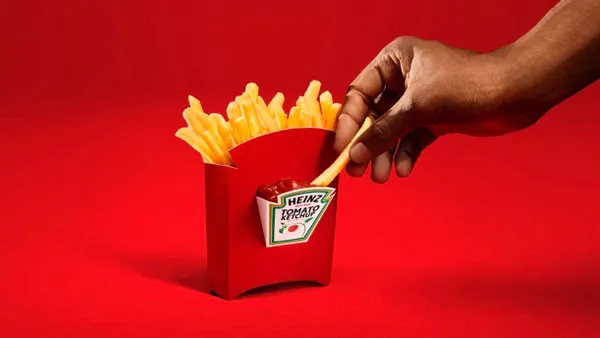

The versatility of WaveKraft mailers makes them suitable across multiple e-commerce industries. In beauty and cosmetics, nail polish bottles, glass cosmetic containers and pump bottles can ship safely without boxes. For health and wellness, vitamin bottles and supplement containers benefit from the cushioning and radial support that prevents shifting during handling.

Lifestyle and retail products including books, clothing and small toys that previously required boxes for protection can now ship in mailers, reducing material costs and freight expenses. Items made from tempered glass, plastics and acrylics can safely ship in mailers with superior protection compared to standard corrugated options.

Bottom Line

The traditional choice between mailers and boxes is being redefined by hybrid solutions that deliver box-level protection with mailer efficiency. For fulfillment operations navigating rising costs, tightening margins and increasing sustainability pressure, WaveKraft recyclable, padded mailers represent a shift in how protective packaging can meet operational, regulatory and consumer demands.