In today’s high-pressure manufacturing environment, time is everything. Production deadlines are tighter. Labor shortages persist. And expectations for faster order fulfillment show no sign of slowing. It’s no wonder that packaging leaders are scrutinizing the time it takes to procure, install and deploy new equipment.

Yet across the packaging industry, one hidden bottleneck continues to slow progress: over-customization.

Historically, manufacturers prioritized specific solutions. Every machine was tailored to exact specs and engineered from the ground up, with custom layouts, guarding and controls. This approach worked well for unique applications. In today’s reality, it often introduces friction: longer lead times, drawn-out quoting processes, complicated installation and greater support requirements.

The lead time trap

Packaging professionals know this story all too well. You get a project approved. A production line expansion or new product launch timeline is set. But when you go to source the equipment, particularly end-of-line automation like case erectors or packers, you’re told the machine will take 16–20+ weeks to build.

Suddenly, timelines are in jeopardy. Capital dollars can’t be spent in the current fiscal year. And worst of all, production schedules are impacted by delays that had little to do with your planning.

That’s why many teams are now asking a new question: “What do we actually need and how fast can we get it?”

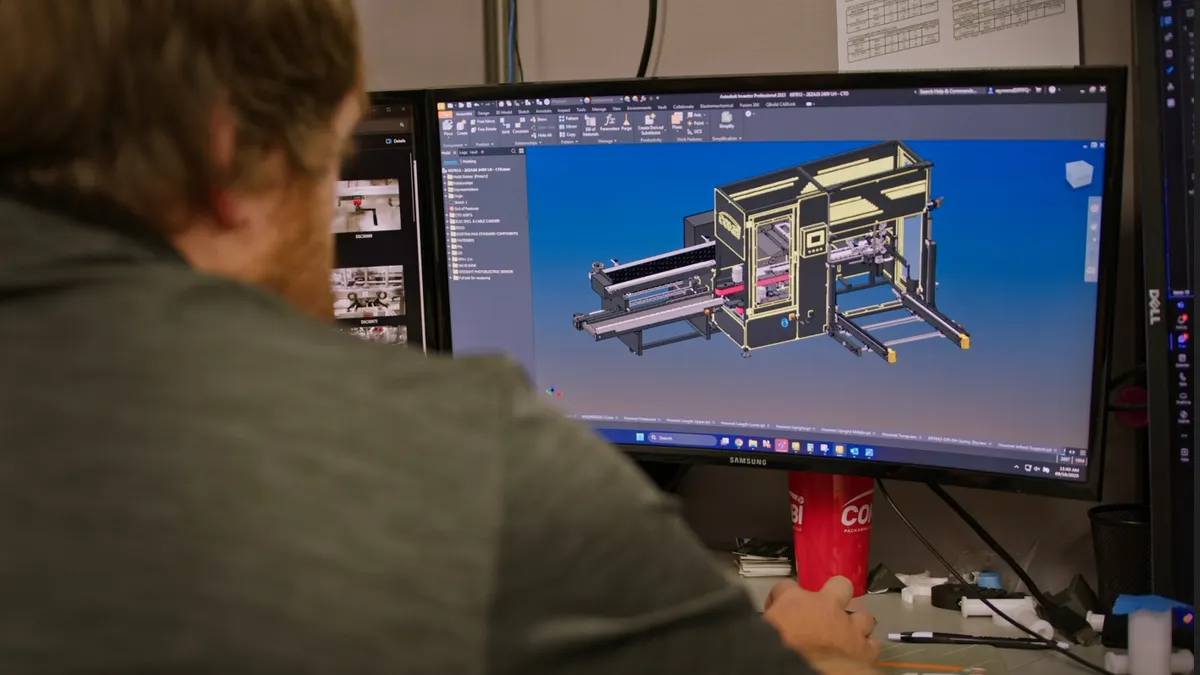

A smarter model: Configure-To-Order

Enter the configure-to-order model; a shift in how automation equipment is sold and built. Rather than starting every machine from scratch, manufacturers are offering a set of pre-engineered options that customers can configure to suit their needs. These modular designs are still flexible, but they’re grounded in field-tested components and proven integrations.

The benefits are clear:

- Shorter lead times. Instead of waiting months, customers can often receive equipment in a matter of weeks.

- Simplified buying experience. Sales teams and customers alike benefit from clarity and faster quoting cycles.

- Reduced implementation risk. Standardized components and tested configurations reduce variability, making commissioning smoother and support more efficient.

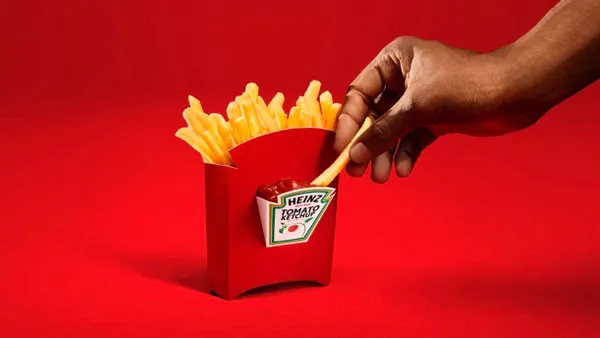

It’s a model that’s gaining momentum, especially in key equipment categories like case erecting. Once viewed as an entry point to automation, case erectors are now strategic assets serving as the foundation of end-of-line performance. Choosing the right one and getting it in place quickly, can make or break a production schedule.

Real-world implications

This isn’t just theory. Across industries ranging from food and beverage to e-commerce fulfillment, operations teams are feeling the pain of delays. In some cases, capital projects have been postponed simply because equipment couldn’t arrive fast enough. In others, teams have been forced to settle for less-than-ideal equipment because longer-lead options wouldn't meet delivery deadlines.

That’s why the market is shifting. Buyers increasingly prioritize availability, ease of integration and reliability over niche custom features. If a standard machine can do the job, do it well and arrive quickly, it often wins.

Balancing speed with quality

Of course, speed isn’t everything. A quick turnaround means little if the equipment doesn’t perform. That’s why configure-to-order systems must be built on a foundation of quality. Field-proven technology, thoughtful design and robust support are essential.

The best equipment suppliers are blending agility with durability ensuring that fast delivery doesn’t come at the expense of long-term performance. That’s what today’s packaging operations need: equipment that works well, arrives quickly and isn’t overcomplicated.

The bottom line

Packaging teams are under pressure to deliver results. And when it comes to automation, the biggest delays aren’t always technical. They’re often the byproduct of unnecessarily complex buying and build processes.

Configure-to-order systems offer a compelling alternative: reliable automation, faster turnaround and a smoother path from purchase to production. As the market evolves, expect more buyers to follow suit choosing streamlined solutions that keep operations moving and business goals on track.