Companies constantly innovate and redesign their packaging to boost performance, enhance sustainability and improve marketability. Here’s a look at three recent packaging product launches or revamps on Packaging Dive’s radar.

Like a ton of bricks

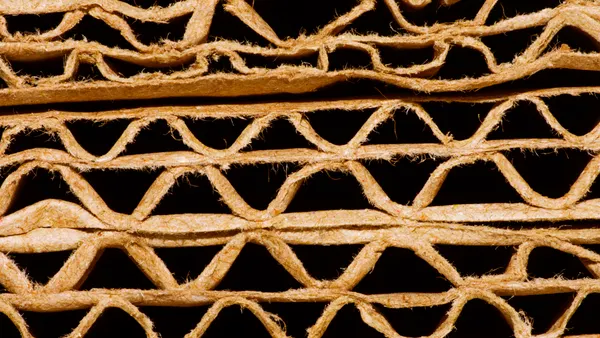

The Lego Group is celebrating a milestone in its fiberization journey as it marks the transition of more than half of its packing lines for the toy bricks to paper packaging instead of single-use plastic bags. The company began this transition in 2022, and now 56% of its machines use “sustainably sourced, technically recyclable paper-based alternatives,” according to a news release.

Five Lego factories are undergoing the change. The lines in China and Vietnam have now largely converted to paper; full implementation is expected at the plants in the Czech Republic and Hungary by 2026; and completion in Mexico is slated for 2027.

The bags are manufactured from material sourced from FSC-certified forests, recycled materials and other controlled sources, the release says. The company will examine ways to make its paper-based packing lines operate faster so they can surpass the output of the previous plastic packaging machines.

“Once the roll out of bags is complete, we’ll explore ways to enhance and continue to make the bags, and the building experience they offer children and families, ever better,” said Jesper Toubøl, vice president of R&D for packing and packaging, in a statement.

Lego reports that 93% of its overall packaging, by weight, is made from fiber-based materials.

What’s old is new again

McCormick & Co. is getting nostalgic with an update to the packaging for its Old Bay seasoning. It’s getting rid of the plastic containers and going back to the original tin substrate.

The company says in a news release that the metal container will maintain the “fan-favorite logo and design” while bringing back “the classic feeling and user experience of years past.”

McCormick switched the Old Bay containers to plastic in 2017, touting the move as being more environmentally friendly due to a 16% reduction of carbon emissions, according to a Baltimore Sun article from that year.

The revamped packaging is hitting store shelves this month.

Worth its salt

Burgopak created packaging for Salt! Supplements’ electrolyte product.

Burgopak’s design team used one of the company’s proprietary coupe packs to house the 15 sachets. A paperboard mailer, made from MetsäBoard Pro FBB Bright, surrounds the pack.

The supplements completely fill the inside of the packaging, which minimizes dead space, according to a news release. The tray presents the products at an angle to provide “a visually interesting presentation with improved dimensions proportions - not too long, not too deep,” according to the release.

“It was essential that the packaging would be both appealing and functional for sportspeople. The feedback we’re receiving is very positive,” said Alfonso Iovine, Salt! co-founder, in the release.