Dive Brief:

- Old corrugated cardboard markets are facing further flux after the Chinese government announced on Oct. 9 that it would require recycled pulp importers to specify whether the material was milled using dry or wet processing methods. The measure also allows for on-site shipment inspections.

- The policy aims to suppress the amount of dry-milled pulp entering the country, as that material is considered more contaminated. OCC, a key feedstock, consequently faces “a black swan event” and prices dipped last week, said Bill Moore, president of consulting firm Moore & Associates, during an Oct. 16 session at the Paper and Plastics Recycling Conference in Chicago.

- U.S. companies are waiting for China to publish information about exactly how it plans to carry out inspections for the pulp shipments and enforce compliance, but the change “has [trickled] down into the market and has everyone spooked,” said David Lee, president at Green Evolution Recycling.

Dive Insight:

Fiber and recycling industry participants are closely watching China’s activity regarding this regulation to determine if it will have a similar widespread impact as some of the country’s other environmental policies and import restrictions during the last decade.

The Chinese government’s Green Fence policy in 2013 and National Sword in 2017 included bans or heavy restrictions on imported materials that were newly classified as waste instead of recyclable. They essentially stopped the country’s imports of OCC and mixed paper.

Multiple other Southeast Asian countries — including Indonesia, Malaysia, Thailand and Vietnam — imposed their own bans or restrictions on various scrap paper imports in the years that followed, fearing they had become the dumping grounds for the world’s waste. India similarly imposed restrictions on fiber material imports.

The regulations caused upheaval in global fiber scrap supply chains. That prompted Chinese importers to turn to recycled pulp imports, largely derived from OCC or mixed paper, to circumvent restrictions on imports of those commodities. In many cases, scrap fiber sourced from the U.S or other Western countries is processed into pulp in other Southeast Asian countries, which is then funneled into China.

The new trade in recycled pulp to China grew tenfold between 2019 and 2023, according to a recent Rabobank report. Prior to this month’s regulatory changes, more than 60% of China’s recycled pulp imports were produced through dry grinding, said Xinnan Li, senior analyst at Rabobank, via email.

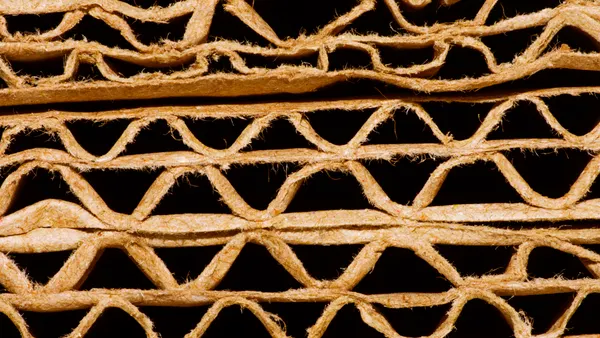

However, the dry method is known to produce bales with higher percentages of contaminants. During the dry process, recycled paper is shredded with minimal screening and no wet pulping, Li said, which “results in higher contamination levels, including plastic and metal fragments.”

The country also has cited health concerns with the dry process, such as bacteria in bales. China considers wet-pulped bales a safer and healthier option because the high-temperature drying process achieves sterilization, according to financial publication Yicai Global.

While China has put dry recycled pulp imports on hold, mills that produce bales using a wet system saw “an uptick in orders over the weekend” of Oct. 10-12, said Matt New, vice president of sales at Ekman Recycling, during the PPRC session. “There’s still the China demand for recycled pulp.”

“The price will probably take a little bit of a dip, I would guess, for the next couple of weeks. But then there'll be that four-week period where nothing was shipped, and I would assume that the demand would increase,” New said.

Pulpers who are currently willing to buy feedstock “smell blood in the water” and are pushing prices down, Lee said.

Dry pulpers in Southeast Asian countries, including Thailand, “are doing a hard stop” on production until they get more clarity on China’s new rule, he said. “In extreme cases dry pulpers are canceling orders and those who had speculative loads on the water without orders are now diverting their cargo to possible wet pulpers.”

Observers are monitoring the situation for potential effects, such as supply chain snags or port congestion for OCC and mixed paper shipments.

“The steamed pulp is sitting in containers waiting to find a home,” Melanie Harman, director of mill fiber procurement at PaperWorks, said during the PPRC session last week. “You have speculators that put fiber out in the market, and they sail the ships and try to find a home when they get on the water. And now they're in distress.”

Although congestion has been reported at ports on the U.S. West Coast, that “has not been due to this issue, as we're not seeing the shipping [repercussions] yet,” said James Derrico, vice president of new business at CellMark. Lee echoed that idea, saying that port congestion is due to multiple factors including shippers’ attempts to avoid tariffs leading to delays. “So, all this maneuvering has caused logistical jams all around,” Lee said.

The measure is not positive for mixed paper or OCC markets, the main one being No. 11 grade, as it introduces uncertainty into a space that already had been experiencing price volatility. OCC prices were up 245% by mid-2024 compared with January 2023, according to analyst estimates, but have been on a steady downward trajectory this year. OCC is typically viewed as one of the most volatile commodities, said conference speakers.

A unique feature of recycled commodities is that material supply is often created by the industry’s own demand, but with a lag time, Matt Elhardt, chief revenue officer at market intelligence company ResourceWise, said during the PPRC session. That means today’s supply of OCC was demand for corrugated boxes three to five months ago, he explained. This dynamic contributes to OCC’s rapid and deep price fluctuations.

“A structural feature is that the industry always has imbalances of supply and demand, almost perpetual, and that's what leads to the volatility,” Elhardt said. “You should expect [OCC] volatility basically forever, until someone figures out a financial instrument to solve it.”

Rabobank expects that China’s regulatory announcement will cause the country’s imports of low-cost, dry-ground pulp to decline sharply in the short term. “Consequently, raw material costs for Chinese paper producers will rise, although weak domestic demand may partially offset the impact,” Li said.

Long-term effects will likely depend on how rigorously the country enforces its rule, sources say.

“The checking of every recycled pulp container along with testing is not easily accomplished, and seems very unnecessary as the quality already being shipped is good,” Derrico said. “In my opinion this is more of a firm warning for the recycled pulp mills to clean up the quality even further.”

Despite the uncertainty, sources agree on one likely outcome: “I personally feel the long-term play is to ban dry pulping," Lee said.