Dive Brief:

- Today Kind Snacks is launching its first retail pilot program in the United States to test flexible paper wrappers, which it says consumers can recycle in curbside programs. The pilot, which runs until Oct. 1, will help inform decisions about the potential for a broader move toward fiber-based wrappers instead of plastic.

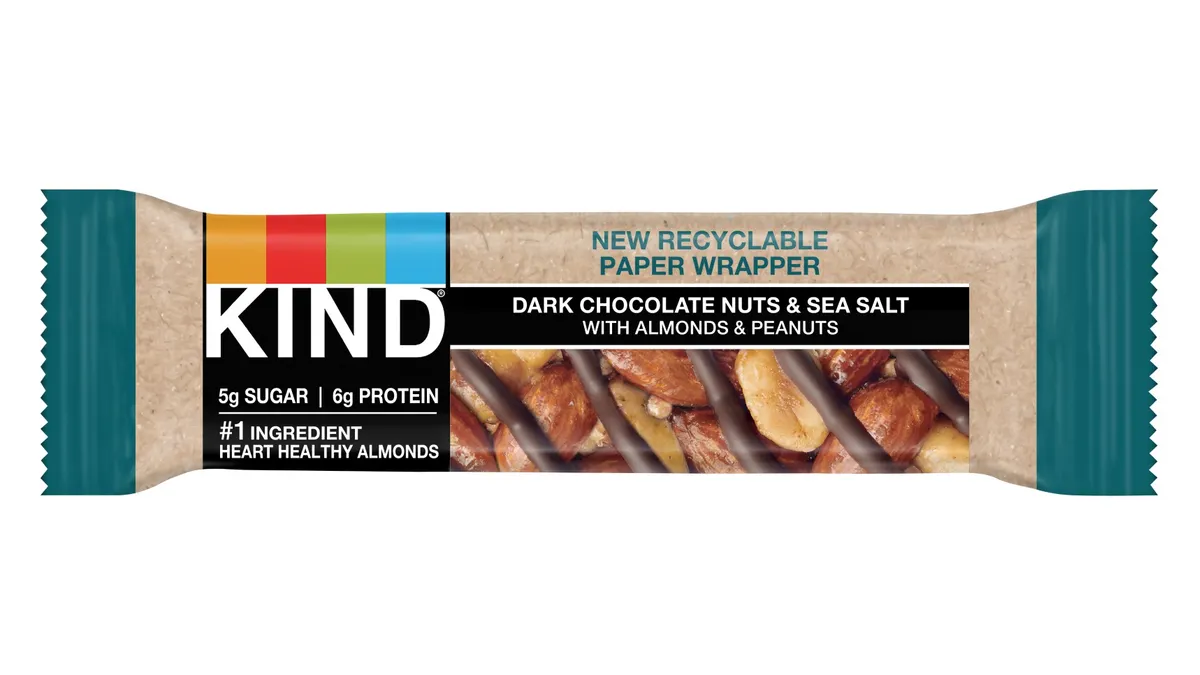

- One of the brand’s snack bar varieties — Dark Chocolate Nuts & Sea Salt — will sport the paper wrappers that are exclusively available at Whole Foods stores across Connecticut, New Jersey, New York, Texas and southern California, as well as select store locations in Louisiana, Arizona and Nevada.

- Kind worked with its existing packaging supplier, Printpack, on this project. Printpack did a lot of the pre-testing and pre-certification work with the How2Recycle program for the new paper wrappers, said Kerri Clark, vice president of packaging research and development at Kind.

Dive Insight:

Kind ran its first pilot program for paper-based wrappers two years ago, but it was more limited in scope. It was solely for 5,000 units available for direct-to-consumer e-commerce purchases made through the company’s website.

“Based on those results, we decided that we wanted to test at scale at the shelf. So that's why we wanted the next test to be with a retail partner,” said Lindsay Philpott, senior manager of sustainability comunications at Kind. The new, in-store pilot allows the brand to “do different types of consumer tests, different types of technical tests” than for the e-commerce pilot, “to make sure that this is something that we wanted to look at scaling in the future.”

Prior to the retail pilot, the paper wrapper underwent on-shelf testing and standard quality control, according to Mark Brogan, vice president of R&D and customer success at Printpack, who responded via email. The packaging company also identified multiple recyclable paper solutions because “supply continuity is very important to assure we mitigate any potential issue,” he said.

Durability was another consideration for material choice, to ensure the product holds up to the rigors of transport and handling throughout the supply chain. Maintaining visual identity was another factor. “Paper naturally impacts color vibrancy and glossiness” in addition to the packaging’s premium feel, Brogan said. Plus, the partners wanted the packaging to clearly look and feel like paper so it is more intuitive to consumers to recycle them curbside, Philpott said.

The paper wrappers have a barrier coating that protects the snack bars from oxygen and moisture, but the companies declined to discuss the specific materials due to the proprietary nature. However, they confirmed no PFAS is included. The paper and barrier’s influence on food product shelf-life is one element under examination in this pilot project.

While Printpack uses digital inkjet printing for some customer projects, it relied on traditional flexographic printing for the paper wrapper pilot. “[I]t was important to utilize a printing process that could be duplicated at scale. Printing surface, drying rates, and selecting the correct overprint varnish were all important factors,” Brogan said.

Ensuring that the paper wrapper is curbside recyclable also was paramount for this project, Clark said. It’s important to make recycling participation easy for the consumer, because “if there's extra steps involved, the adoption rates start falling off pretty quickly,” she said. The labeling also states that the wrapper is paper and recyclable.

Kind also is working on another wrapper innovation to improve sustainability, Clark said. The existing wrappers are a traditional, complex lamination, she said, explaining that “we are almost fully transitioned to monomaterial plastic.” The company is “taking a bit of a phased approach on sustainability.”

That phased approach and the desire for developing scalable sustainability initiatives led Kind to run the paper wrapper as another pilot project instead of launching as a full-scale, permanent addition, Clark said. “There are many things we need to learn to be able to scale big,” she said.

Other packaging companies also are working with food customers on paper-based flexible packaging. For instance, Amcor announced in April that it's working with Riverside Natural Foods to launch curbside recyclable, paper-based wrappers for MadeGood Trail Mix bars.