Dive Brief:

- Sonoco is investing this year in four U.S. facilities to expand manufacturing of its rigid paper cans with paper bottoms. The company did not specify the level of funding, but a spokesperson called it a multimillion-dollar investment.

- The company plans to expand production and add new lines at existing manufacturing facilities. It aims to install new paper-bottom presses and can lines at facilities in West Chicago, Illinois; Greenville, Wisconsin; Dayton, New Jersey; and Norwalk, California.

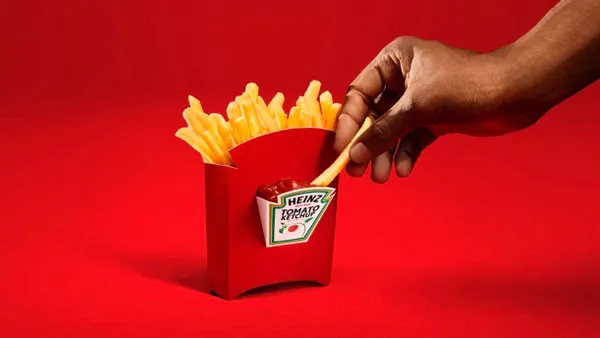

- Sonoco started selling this type of fiber container in the U.S. last year following a 2023 launch in Europe for cans of Kellanova’s Pringles. Executives have said that the product drives sales growth, making it a key area for investment.

Dive Insight:

During an investor day event in February 2024, Sonoco executives highlighted the new paper-bottom Pringles can and its sustainability attributes. “It’s the single biggest innovation that that pack has seen since the 1960s,” said Sean Cairns, president of the global rigid paper and closures business, during the event. Sustainability is a key trend driving growth in the company’s rigid paper containers business, and paper is “clearly the preferred substrate of CPGs and other end consumers,” he said.

The chips brand’s switch from metal to paper-bottom cans grabbed attention for its potential sustainability benefits. The monomaterial containers are designed to make recycling easier.

Although recyclers’ acceptance of fiber cans with metal bottoms, like the traditional Pringles cans, is increasing, it’s still not considered mainstream. Earlier this year, How2Recycle announced that it’s upgrading the status of composite canisters with steel bottoms in the U.S. from “not yet recyclable” to “check locally.” It credited Sonoco with helping to improve recycling outcomes for these products — which is separate from the company’s work on recyclable paper-bottom cans.

The paper-bottom can has a spiral-wound body and a fiber insert, and it’s made from recycled board, said Scott Byrne, executive vice president of global sustainability at Sonoco. “You also get a lower carbon footprint” from manufacturing these than previous versions, he said.

“I think the paper-bottom format is looked at in both the EU and North America as kind of your direction for new product development,” he said. “We see that drive for circularity.”

The company is focusing on the North American snack category for paper can expansion. Those customers have expressed interest in sustainable container solutions in response to factors like increased packaging regulation, Byrne said. Sonoco is “making sure [we’re] ready for growth, not just in snacks, but also in different areas like powdered products and then also pet treats,” he added.

Investments for U.S. paper can manufacturing initially will center on the Midwest and then move to other regions, Byrne said. Chicago is a leading national hub for food manufacturing, especially snack foods. In the future, Sonoco might expand paper can investments across its footprint, based on customer demand, he said.